Our services

&

Drug development services

1. Pharmaceutical Development

Our team combines expertise in drug formulation development for generic applications or new chemical entities with an understanding of commercial pharmaceutical manufacturing processes for long acting forms, sterile injectables and hormonal tablets.

Our research scientists will collaborate from the very beginning of the project with your team to make sure that all the development learnings transfer appropriately to full scale manufacturing. Throughout the development stages, our experts will work together closely to ensure the project is at all times aligned with your defined objectives.

- Raw material sourcing

- Compatibility testing API-excipients-packaging components

- Reverse engineering of the original drug product (generic development)

- Full polymers characterization (DSC, RAMAN…)

- Forced degradation studies

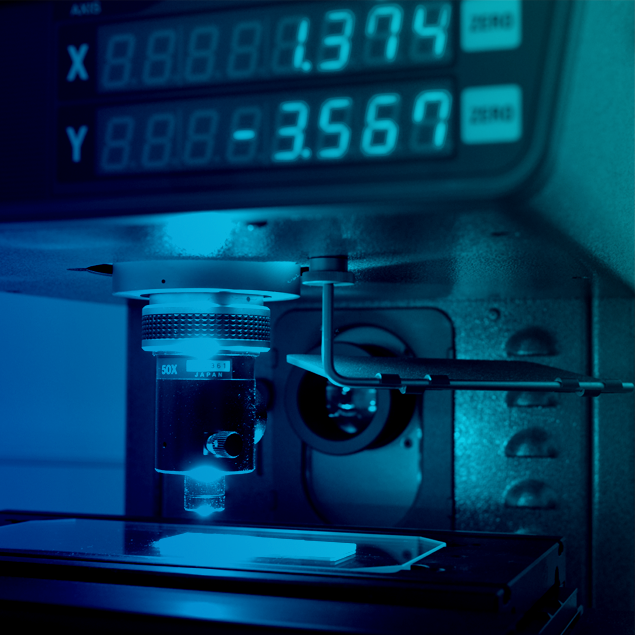

- Development of physico-chemical characterization methods: discriminative in vitro dissolution/diffusion test, particle size distribution, DSC, rheology/viscosity, pH

- Lab scale formulation screening

- Full quality control strategy

- Stability studies (ICH conditions)

- Quality assurance support in compliance with ICH Q8, Q9 and Q10.

From proof of concept to commercialization we will develop the right processes for your product manufacturing.

Product life cycle scalability of formulations (early pilot studies, clinical trial materials, commercial batches), technical transferability (e.g. clinical trial material or manufacturing optimization) are assured at all times thanks to a seamless collaboration between our development and manufacturing teams all on one site.

- Laboratory, pilot, cGMP-compliant clinical trial materials and cGMP commercial scale

- Process identification, evaluation and selection,

- Development of specific equipment (assembly steps…)

- Process optimization

- Site and technology transfers

All analytical capabilities needed for outsourced formulation development and manufacturing activities are provided by Mithra.

Our services:

- Study of active ingredients

- Development and validation of analytical methods for drug products, raw materials, cleaning methods

- Development and validation of diffusion profiles (for long acting products)

- Development and update of analytical methods for degradation products (ICH Q3B)

2. Clinical Supply Manufacturing

At Mithra our goal is to meet your specific needs to support your business at all times. We offer tailored clinical manufacturing services to ensure a successful launch of your clinical trial: we develop your product according to your technical requirements within your timeframe.

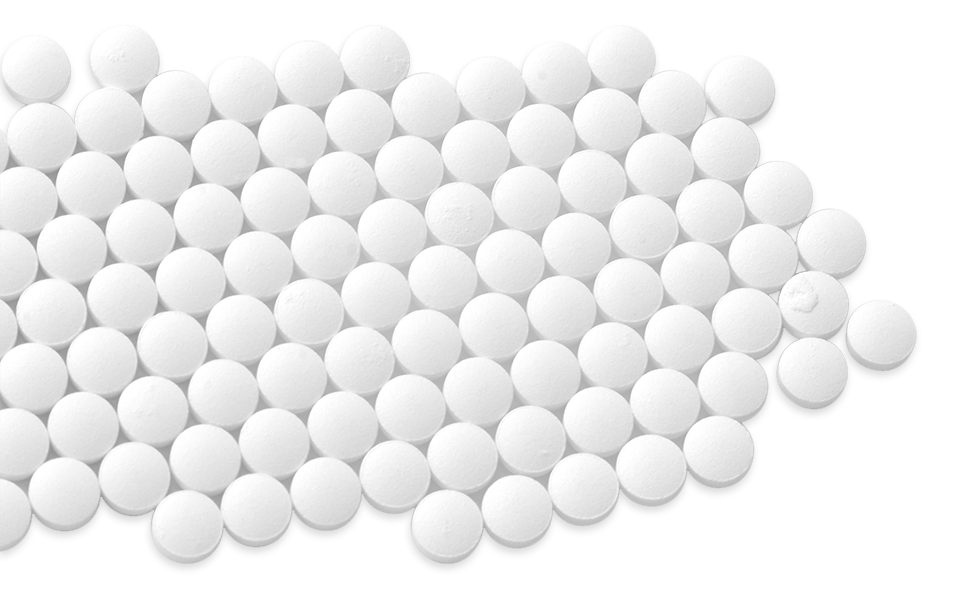

We offer efficient, flexible, clinical manufacturing capabilities, covering hormonal tablets, long acting products and sterile injectables.

We also provide all the manufacturing and packaging capabilities for your clinical trials.

Our manufacturing team is supported by analytical labs enabling continuous monitoring of your product progress.

Our services

- Technology transfer

- Process qualification / optimization

- Clinical GMP manufacturing

- QC release

- Clinical trial packaging and supply

- Stability studies

3. Stability Studies

We offer stability testing under International Conference on Harmonization (ICH) conditions and custom conditions.

- Informal, formal, accelerated and long-term stability conditions

- ICH or custom conditions

- Physical, chemical and microbiological

- Freeze/thaw studies

- Photostability

- Bulk holding time

4. Contract manufacturing

With its new state-of the art facilities, Mithra CDMO is the flexible and cost-effective solution for your contract manufacturing needs from pilot batches to clinical trials materials, to full-scale commercial cGMP production.

Mithra is committed to develop flexible solutions to meet your needs through our global facilities and internal project management system which meet the most demanding requirements of today’s pharmaceutical industry.

We provide cGMP manufacturing support in a comprehensive range of batch sizes for liquid injectables, long-acting products and oral forms.

5. Logistics and Supply Chain

Supply Chain Management covers all activities that are needed to make a product available to our customers – from the point of sourcing raw materials until delivery and invoice settlement for the final product.

Global and strategic Supply Chain Management is a core business of Mithra CDMO.

We offer the following services:

- Collaborative demand planning with customers

- Alignment of customer demands with capacities and raw material supplies

- Securing customer deliveries in requested time (distribution hubs, stocks, proper logistics and transportation services)

- Prompt and reactive communication to customers

- Definition and monitoring of KPIs in order to steer the business and to improve the value chain (perfect order fulfillment, delivery performance, customer order lead time…)

- Improvement of existing business processes with regards to Economics (value stream analysis and optimization, quality management, portfolio management…) and Service orientation (delivery / distribution concepts, better planning, reduction of lead times…)